Assembly of Cima1915 products is one of the most delicate production stages. Full compliance with the production and assembly regulations for components is what gives the Cima wheel drive unit most of its quality. That is how dozens of elements coming from very different procedures can give life to a product that is unique in quality, performance and duration.

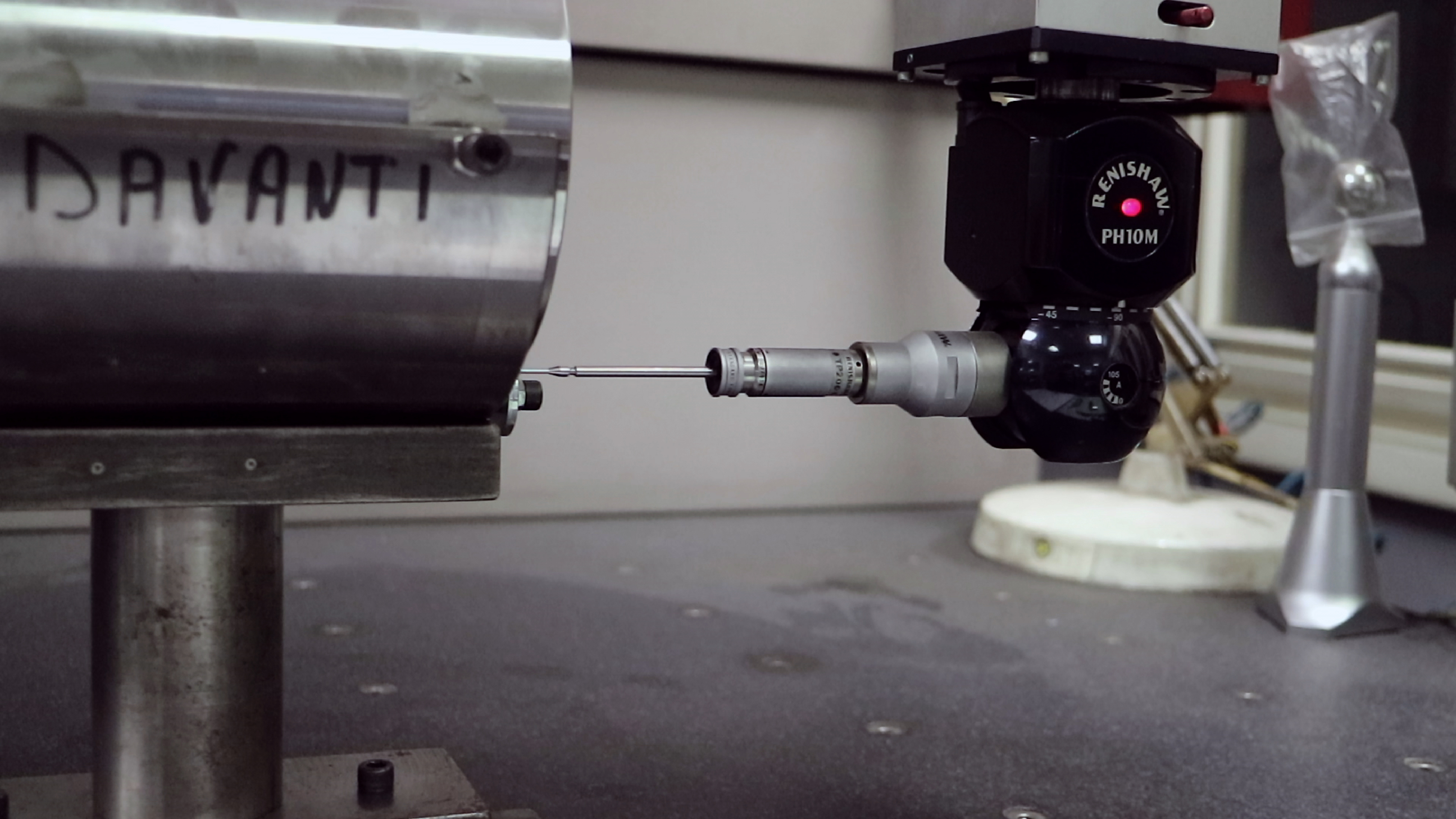

This short video describes the daily job of the 3D testing machine while it checks a component with centesimal precision. Tubes, fusions, cogs, coils, stators and coated wheels go through dozens of highly accurate controls before entering the robotised assembly line.

At the end of this process, when all intermediate electro-mechanical controls have been satisfied and the optical-aesthetic ones have also been passed, the finished product is tested one more time. It is when data measured meets the harsh protocols imposed by Cima1915 that the wheel drive unit finally moves on to the packaging department.

Click here and enjoy the movie clip

110 years of family business history

Scan the QR code on the label of each CIMA product

All eyes on electric propulsion in Amsterdam from 19-21 November

A floating lab created to develop electric propulsion

Cima1915 back to METS

Cima1915 at Electric & Hybrid Marine Expo Europe

Cima1915 motor wheel drives RCM to the Amsterdam Innovation Award 2022

Cima1915 Events

Stables automation

Deigma by Cima1915

New G2190, the XXL Motor Wheel

The role of the electric motor in Hydraulic Power Packs

There is increasing talk of 'Green Deal' in agriculture

CIMA1915 is facing the COVID emergency with an investment in Technology

CIMA1915 latest-generation novelties in a movie.

Quality takes another step forward

Warm reception at METS for Deigma

Preview at METS Trade, Amsterdam: Cima1915 presents Deigma

1930: Cima and the inauguration of the new Stazione Centrale

Cima1915 at METS Trade in Amsterdam

Today more than 500,000 vessels are equipped with Cima1915

Assistance Cima1915: we are always ready (although its is likely that you won’t need it) ;-)

The daily job of the 3D testing machine at Cima 1915

1915: Cima’s beginnings in Largo Donegani

Green Vocation - Cima 1915 in the fore promoting an authentic green economy

Lateral with SuperElastic, the most innovative solution for outdoor use

New products: new dimensions for G2 190

Automation in farming becomes a reality